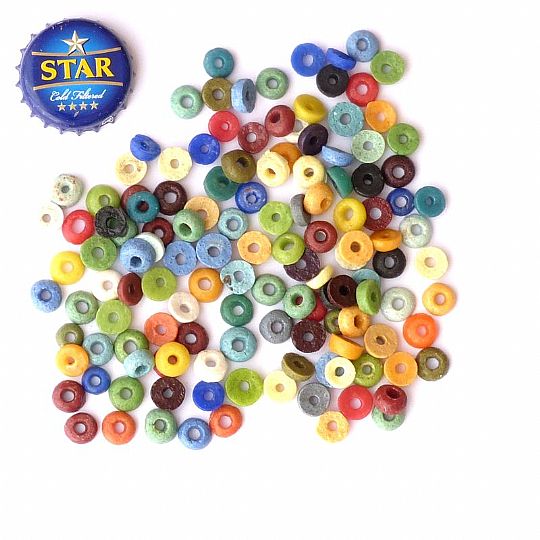

Recycled glass beads, handmade in Ghana

These colourful glass beads are made from recycled glass by our friend Yohanes Nahr in Koforidua. We love the variety of colours he produces. As these beads are handmade, sizes and colours are not exact - all part of their rustic appeal.

Bead and pack sizes:

- 15mm: 25g packs, approx 20 beads

- 9mm: 20g pack, approx 65 beads

- 7mm: 15g pack, approx 120 beads

- Waist Beads 3mm: String approx 65-70 cm / 26-27 in, approx 230-240 beads

Bead size and scale

As a visual clue to the size and scale of our beads, we use a Star beer cap in our bead images. Why Star? Because it's the major beer of Ghana where most of our beads are made. Also, on the buy pages, we indicate approximate bead dimensions in millimetres.

More: About Ntaka glass beads

Meet Yohanes Narh: master bead maker

We buy all of our Ntaka glass beads from our friend Yohanes Narh in Koforidua, Ghana. We've known Yohanes for many years. There are other Ntaka bead makers around, but for colour and quality, Yohanes is the best.

Making Ntaka recycled glass beads

Yohanes, his wife Comfort and his daughter Salome work in the shade of an open-air shelter in their village.

Their raw material is recycled glass, which they find themselves or buy from the itinerant glass vendors at Koforidua's weekly bead market. They use all sorts of glass: bottles, jars, windows, almost anything made of glass.

To begin, they smash the recycled glass into sharp shards, which they then grind using a mortar and pestle into a fine powder.

Next, comes the colour. In order to achieve consistency for our orders, we have worked with Yohanes on a specific African Fabric Shop colour chart. Yohanes refers to this chart and his 'recipe book' before mixing the correct quantity of ceramic dye with the recycled glass powder.

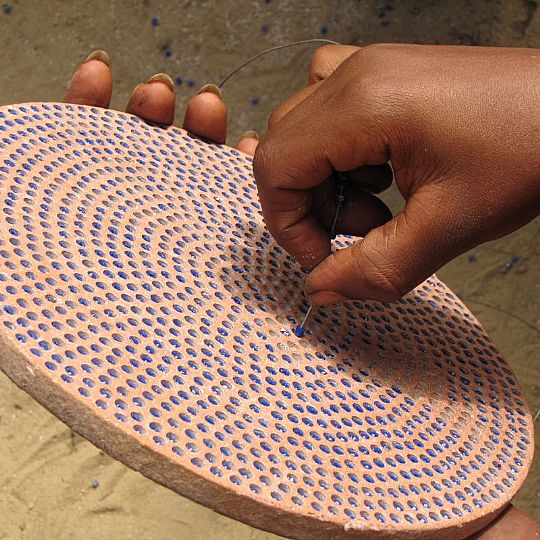

Ntaka beads come in several sizes: 35 mm discs, 15 mm, 9 mm, 7 mm and tiny Waist Beads. Yohanes has a variety of clay moulds on hand for each size.

Filling the moulds with the powder glass and dye mix is painstaking work. A cassava stalk in the centre of each bead cavity creates the bead's hole. Yohanes won't waste even a gram of precious glass powder. He uses a feather to dust any excess powder back into his stock bowl.

When the moulds are ready, they are fired in a basic kiln. The kiln is a hollow mound of mud containing old car springs which form a 'grill' to support the moulds. Below the springs is a blazing wood fire: fire wood is the beadmaker's most expensive material.

The intense heat of the fire fuses the powdered glass into beads, still glowing orange as the mould comes out of the kiln. Yohanes uses a pair of awls to rotate and manipulate each bead in the mould, refining and smoothing its shape.

After the beads cool, they are polished in a concave stone using a light mix of sand and water.

Finally, Salome strings the beads for us to collect when we come to the village.

Yohanes and Comfort in their workshop near Koforidua, Ghana.

Yohanes and Comfort in their workshop near Koforidua, Ghana. Yohanes fills the mould with recycled glass powder mix and smooths away the excess with a feather.

Yohanes fills the mould with recycled glass powder mix and smooths away the excess with a feather. Ntaka bead moulds in the kiln.

Ntaka bead moulds in the kiln. Salome polishing Ntaka waist beads.

Salome polishing Ntaka waist beads.

Multi-buy saving - Mix 'n' Match

Any 10 for the price of 9

Applies to all £2.35 packs of beads. Your discount will be applied automatically at the checkout.